Agriculture

Applications

Various Products of Sagar

Trusted Best Company...

About Sagar Polytechnik Ltd.

Sagar group of companies, Est. in 1988, a reputed group have promoted Sagar Polymers. The company was established in the year 2000 and has gained high reputation in the field of manufacturing different types of PVC, CPVC, HDPE, PPR - pipes, fittings & hoses and Drip & Sprinkler Irrigation Systems etc. in a wide range of quality and sizes.

+

Years In Business

+

Products

+

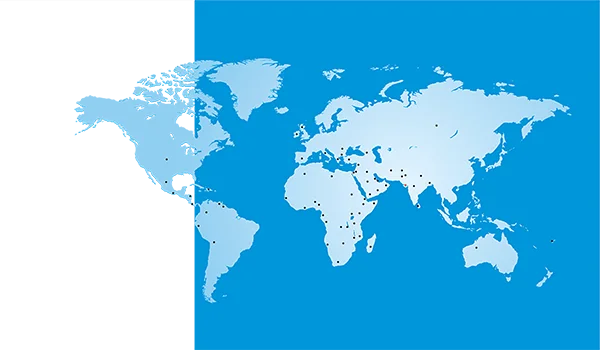

Exports Countries

+

Our Main Applications

What we do...

Explore Our Products

Agriculture

uPVC Column Pipes

Agriculture

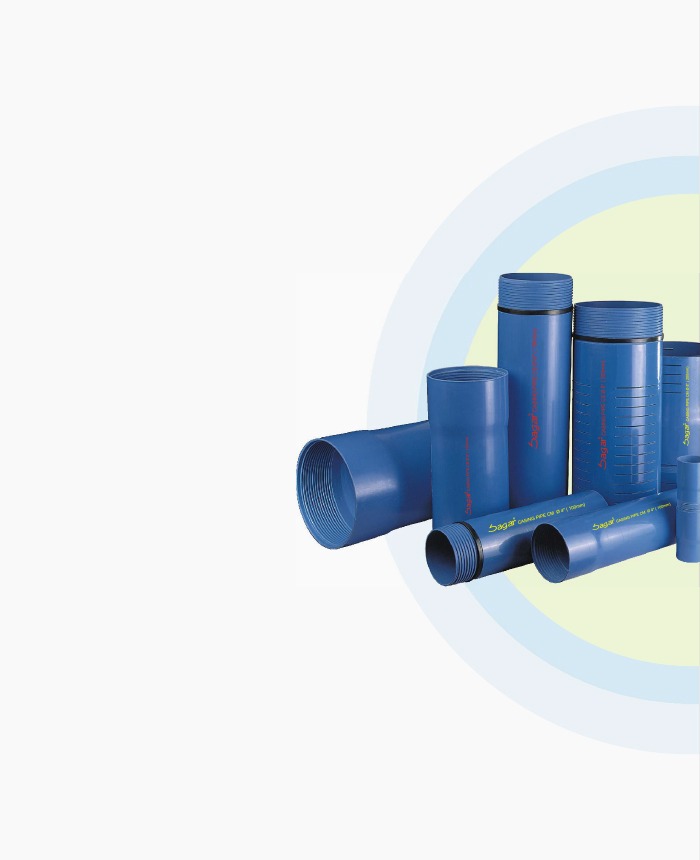

uPVC Casing Pipes

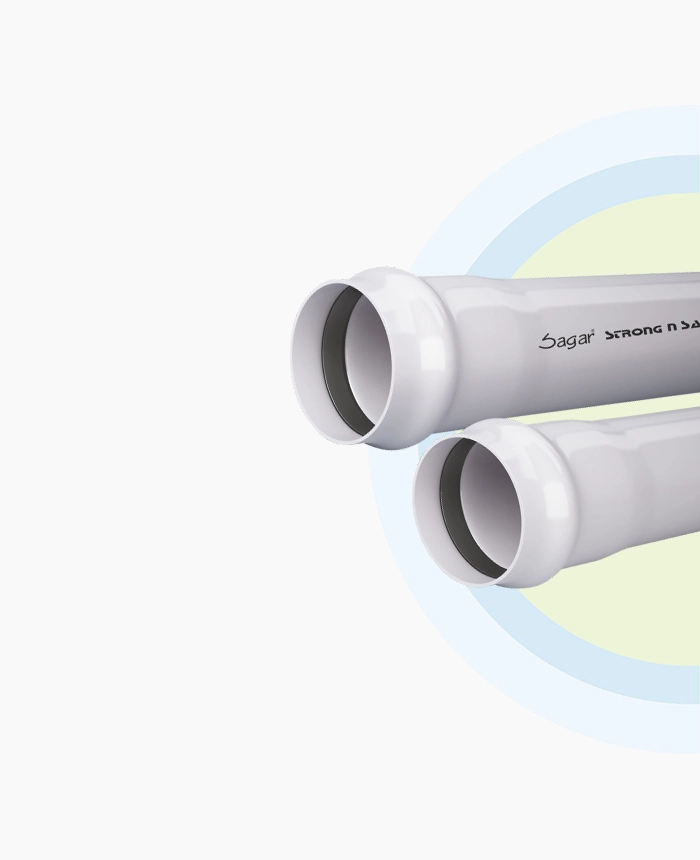

Plumbing

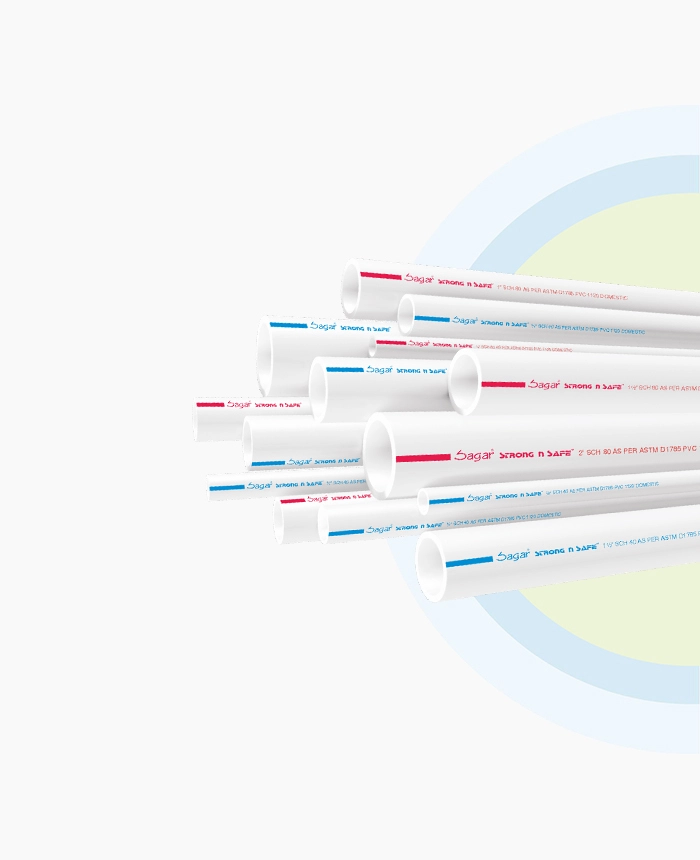

UPVC Pipes

Plumbing

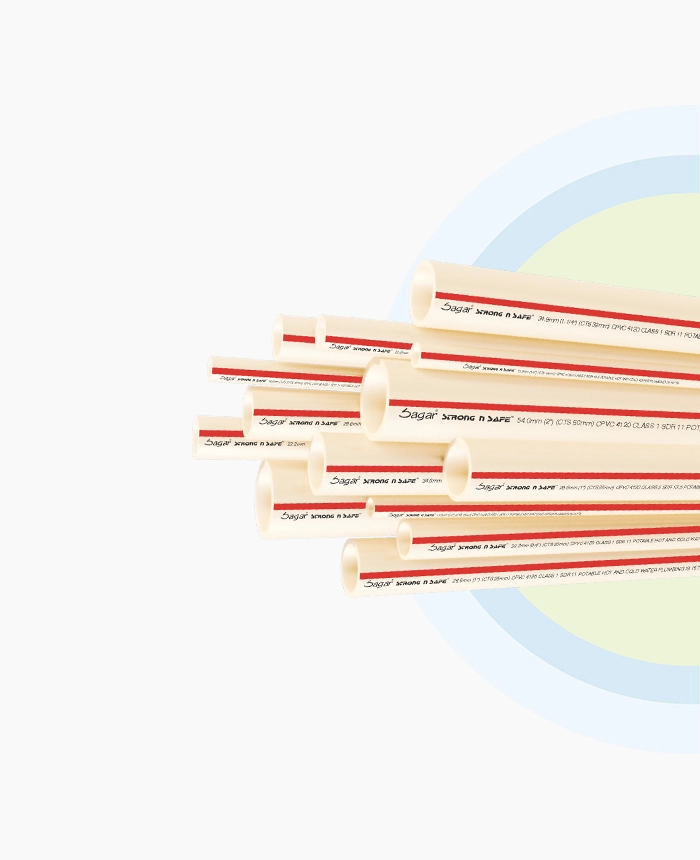

CPVC Pipes

Plumbing

CPVC 40 & 80 Pipes

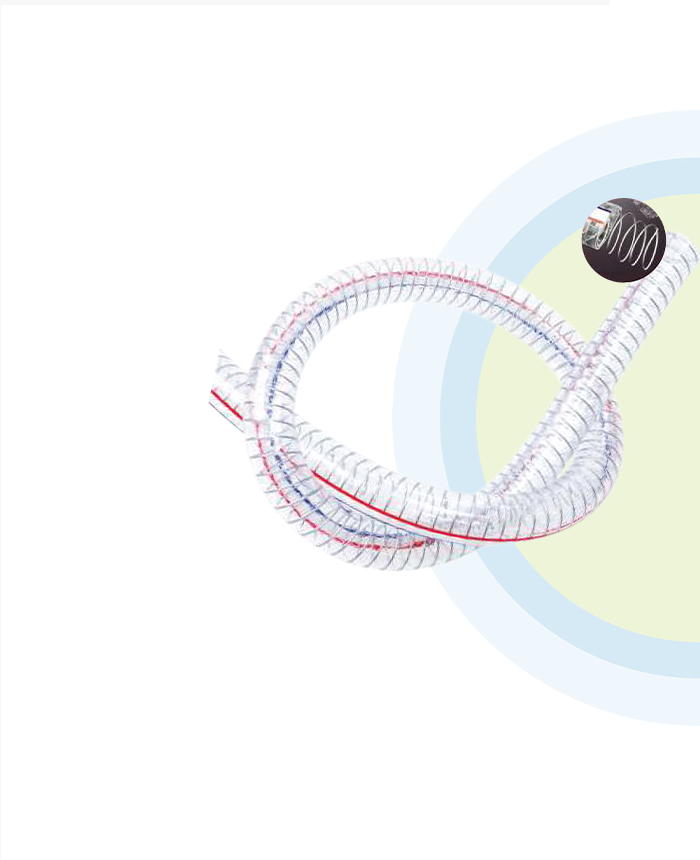

Industrial

Steel wire hose

Agriculture

PVC lay flat hose

Water Distribution

uPVC Ringfit Pressure Pipe

Agriculture

PVC Suction hose

Industrial

PVC GARDEN HOSE

01

Our Vision

The company foresees to become a pioneer in innovating newer products, creating brand value, enhance quality of products and thereby increasing its market share.

View Details 02

Our Presence

Sagar group of companies is a business empire built with a core purpose to improve people’s lives by manufacturing reliable products that enable efficient transportation of water – one of the five elements of nature.

View Details Request a Quote